What You Need to Know

Cost: $31

Time: 2 hours

Difficulty: Medium

Equipment for Squatting, Benching, and Pressing

Material Needed:

- 3, 5 gallon buckets

- 3, 50lb. bags of Quikcrete (fast setting)

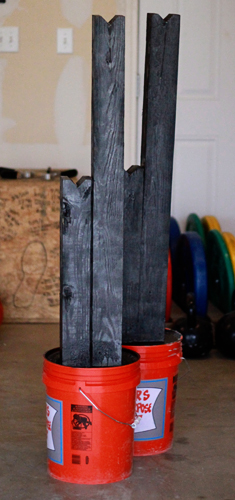

- 2, 8ft. 4×4’s

Step 1:

Go to your local hardware store and pick up your items. At Home Depot they will make 2 cuts for free. I had them cut the 8ft. piece at 5ft., which gave me (2) 5ft. pieces and (2) 3ft. pieces. Take into account how high you want your stands. I originally had it at 60 in. (5ft.), but decided I wanted it a little shorter after I started the project so I had to make two more cuts. I ended up with  (2) 3ft. pieces and (2) 55in. pieces. I am 5′ 11″

Step 2:Â

Make your V-Cuts. If you have a skill saw, put it at 45 degrees and make the cut. This step was far more complicated than it needed to be, but if you mess it up you are screwed. If you are unsure how to make a V-Cut, Click on the Diagram picture to enlarge. If you are using a handsaw, just draw a V and cut accordingly. Any questions on this, let me know.

Step 3: Cement Work

Not as many pictures of these steps because it is a little messy and involved.Â

There are directions on the back of Quikcrete for setting a fence post, DO NOT use those directions. Mix all of your cement in your 3rd bucket, that is why you bought it.

Cement Tips:

- Mix small amounts of the bag of dry cement with water, until you eventually use the whole bag

- Do not mix more than one bag at a time

Recap:

- Duct tape smaller and large post together

- Put in one of the dry buckets

- Mix cement

- Pour mixed cement around post

- Let Dry

That’s it! I had some old spray paint I wanted to get rid of so I added that in at the end.